43 high pressure processing labels

10000 PDFs | Review articles in HIGH PRESSURE PROCESSING Explore the latest full-text research PDFs, articles, conference papers, preprints and more on HIGH PRESSURE PROCESSING. Find methods information, sources, references or conduct a literature ... Labels - BASF Labels. We offer a wide range of acrylic polymer dispersions and UV-curable acrylic hotmelts, which are used in the production of PSA for both paper and filmic labels. The consistent quality of our Acronal ® dispersions as well as their high mechanical stability allow our customers to keep their production constant, minimizing adhesive-related ...

› sterile › basicsBasics on Processing & Sterilization - University of Rochester Sterile Processing Departments are typically divided into four major areas to accomplish the functions of decontamination, assembly and sterile processing, sterile storage, and distribution. In the decontamination area , reusable equipment, instruments, and supplies are cleaned and decontaminated by means of manual or mechanical cleaning ...

High pressure processing labels

› article › 63090-meaningWhat Is the Meaning of Nutritional Value? | livestrong Oct 14, 2019 · According to the Mayo Clinic, added sugars are sugars and syrups that make their way into food during processing. They're commonly found in sodas, desserts, candy, energy drinks and more. The 2015-2020 Dietary Guidelines recommend dedicating no more than 10 percent of your daily calories to added sugars (which equates to 50 grams for a 2,000 ... High Pressure Processing (HPP) Advantages - Hiperbaric HPP allows R&D teams to develop innovative products for the consumer and open new market niches. Increases the Extraction Yield of Shellfish Meat. HPP, at low pressures (3,000 bar), is used for opening bivalve mollusks and removing meat from crustaceans, increasing efficiency and minimizing labor. Eco-friendly. The Basics of a Pressure Sensitive Label » Labeling News We are the experts in label converting and label applications. Our converting facilities can manufacture any type of label you might need, or we can help you create a custom label for a demanding application. Do you need to improve your labeling operations? ID Technology can help. Call us toll free at 888-438-3242.

High pressure processing labels. Health-Based a Top Trend in High Pressure Processing HPP aligns with consumer health trends. Getty. Probably the fastest growing category for High Pressure Processing (HPP) is health-based beverages and immune-boosting shots, according to Errol Raghubeer, Ph.D., VP of HPP Microbiology and HPP Science with JBT Corporation, in a PACK EXPO Las Vegas Processing Zone presentation. High pressure based technologies for clean-label food products - OHIO ... The influence of various high pressure process parameters including pressures, temperatures, dwell times, and shear intensity on microbiologicalinactivation suspended in low-acid food matrices will be studied. A pilot scale UST equipment will be constructed for the evaluation of food quality, nutritional and sensorial benefits of selected low ... › usa-en › productsPressure Transducers and Transmitters - TE Connectivity It normally causes the zero reading to go high or low over time. Independent tests carried out have shown this number to be <.25% under the influence of temperature and pressure cycling for 1500hrs. Read More: Pressure Transducer Frequently Asked Questions New 'high pressure certified' seal to hit stores in the next 90 days High pressure processing (HPP) - whereby foods or beverages (often in their final packaging, which must be flexible) are put into a high-pressure chamber that is flooded with cold water and ...

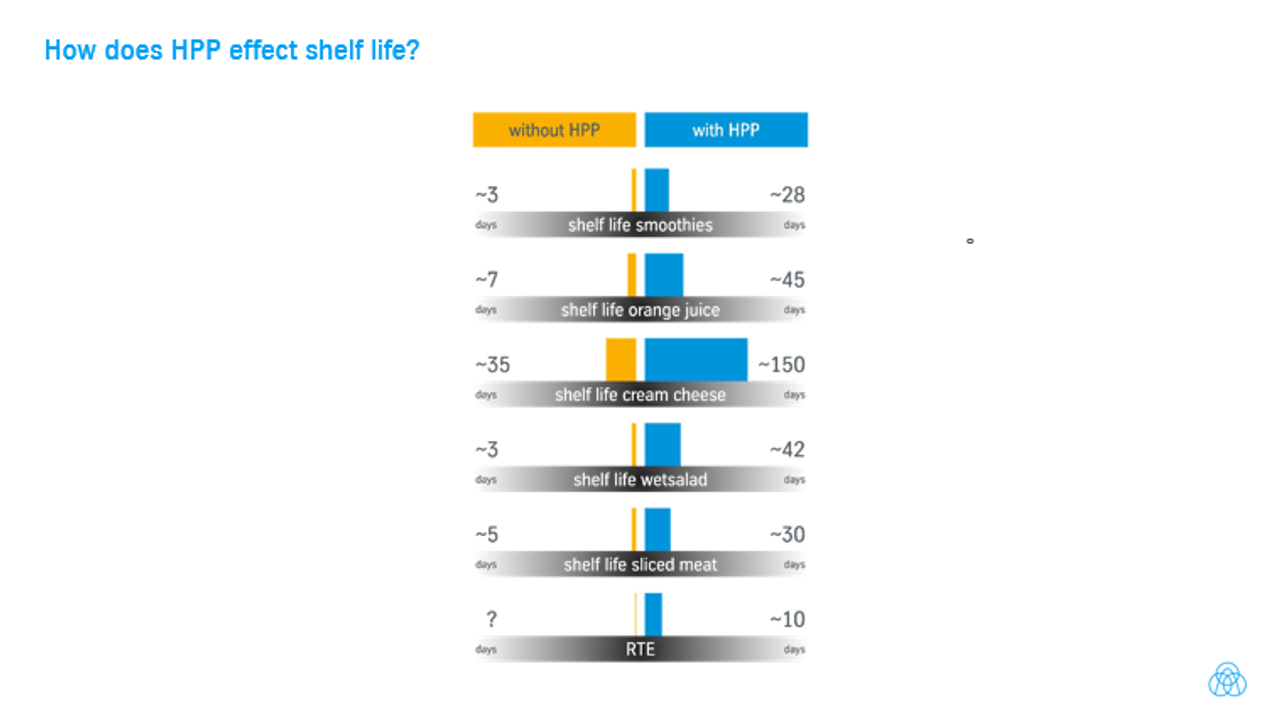

HID® High Temperature Label - HID Global RFID Technology | HID Global They are especially useful for tracking both work-in-progress and finished goods for: industrial tools, medical trays, heavy equipment, car and aerospace components, cargo containers, and even blade and rack servers. Key Features High heat - endures up to 446° F (230° C) Impermeable - repels fire, moisture, oils, petroleum and salt mist Universal Pure | High Pressure Processing (HPP) Services This non-thermal pasteurization technique harnesses the power of extreme pressure (up to 87,000 psi - think bottom of the ocean) to comprehensively crush and inactivate foodborne bacteria and other illness-causing, vegetative pathogens (E. coli, Salmonella and Listeria monocytogenes), molds and yeasts. In doing so, HPP also maintains the optimum attributes of fresh products over an extended shelf life without compromising the nutritional value of the food. › enInnovative labels. Smart solutions. | Schreiner Group Schreiner Group has international production sites in Germany, the United States, and China with identically high quality and technology standards as well as corresponding certifications. Production operations at Schreiner Group’s headquarters in Oberschleissheim near Munich are additionally certified according to the highest security ... Label Materials For High Pressure Processing | SheetLabels.com To reduce contamination in the packaging process, food or beverages that go through HPP are packed, sealed, and labeled before they go through high pressure processing. So, the product label, package, and the food or beverage item are all exposed to hydrostatic pressure of up to 600 MPa or 87,000 pis during HPP.

› Blood-Pressure-Monitor-Wrist-CuffAmazon.com: HealthSmart Digital Elite Wrist Blood Pressure ... HEALTHSMART DIGITAL BLOOD PRESSURE MONITOR FEATURES: • High Contrast LCD screen displays time and calendar • 120 reading history with date and time stamp • Convenient low battery indicator • Blood Pressure Monitor Package Includes: Sleek carrying case, 1 High Contrast LCD monitor, 2 AAA Batteries, 1 wrist cuff size: 5 ¼ by 8 ½ inches ... American Pasteurization Company American Pasteurization Company (APC) is the first company in the United States to offer High Pressure Processing (HPP) on a commercial tolling basis to the food manufacturing industry. HPP kills bacteria that can cause spoilage and food-borne illness, and greatly extends shelf life. Applying HPP to foods and beverages - rather than heat pasteurization - results in products with a fresher ... High-Pressure Processing for Avocado Products: Shelf-life Extension ... High pressure processing (HPP) is the only non-thermal preservation technology for avocado products that meets the high-standard requirements of both consumers and manufacturers: premium quality, clean label, safety, and extended shelf-life. ... Shelf-life Extension, Clean Label and Premium Quality. We will host the English webinar on Wednesday ... Over pressure: Singapore scientists claim HPP could create clean label ... A proof-of-concept study by the Singapore Institute of Food and Biotechnology Innovation (SIFBI) has found that high pressure processing (HPP) of plant protein could produce a clean label plant-based yoghurt with desirable texture and nutrition, comparable to commercial dairy yoghurts.

In situ immunofluorescence labelling of high pressure processed garlic ... Download scientific diagram | In situ immunofluorescence labelling of high pressure processed garlic cell with LM 19 (A-untreated; B-HHP treatment at 200 MPa; C-HHP treatment at 350 MPa; D-HHP ...

High Pressure Processing Labels for Rolls / HPP approved High Pressure Processing Labels for Rolls / HPP Approved. Order: 1-888-791-9590. ... Sample Request; Sheet Labels. Paper Labels. Bright White; Super Permanent; High Gloss; Carpet, Wood, Tire Label; Matte Block-Out (Opaque) 100% Recycled; Photo Gloss (Resin Coated) Piggyback Label ... Looking for die-cut labels? Our sheet labels and stickers can ...

Labels and Tags for Metal Manufacturing - Polyonics Label and Tag Materials For Metals - Forged Under Fire. The HIGHdegree line is rated up to 1112°F (600 °C). Throughout the metal manufacturing process, labels or tags may be applied directly to or hung from the following metal products: Coils Rolls Bars Sheets Rebar Tubes Wire bundles Superior Durability and Quality Label and Tag Materials

Pressure Sensitive Labels | How Are Labels Made? - Prairie State Group That means, your pressure sensitive labels will be printed with the highest level of food safety and quality (SQF) and accurate color targeting. PSG can also offer a wide variety of flexible packaging solutions to compliment your label order. From stand up pouches to stick pack, we can offer a one-stop source for your printed labels and packaging.

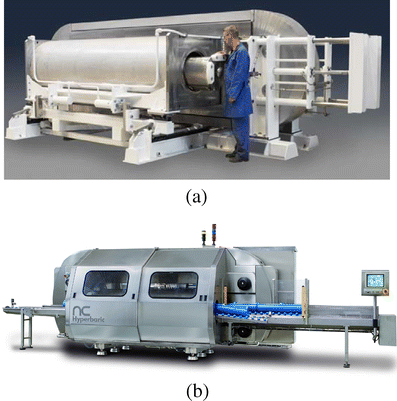

What is High Pressure Processing (HPP)? - Hiperbaric Hiperbaric is the world leading manufacturer of High Pressure Processing machines for the food and beverage industry with 60% of the global market share and more than 20 years of experience. We offer the widest and most reliable HPP machine range meeting the requirements of all our clients from start-ups or SMEs to large multinational companies. We also provide all type of HPP automation solutions to optimize your production line.

› diseases-conditions › high10 ways to control high blood pressure without medication Jul 12, 2022 · Exercise can also help keep elevated blood pressure from turning into high blood pressure (hypertension). For those who have hypertension, regular physical activity can bring blood pressure down to safer levels. Some examples of aerobic exercise that can help lower blood pressure include walking, jogging, cycling, swimming or dancing.

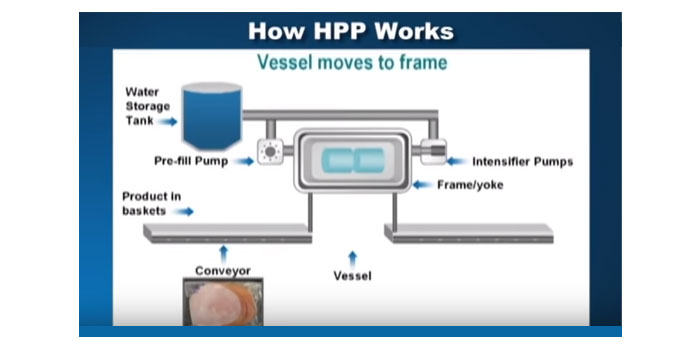

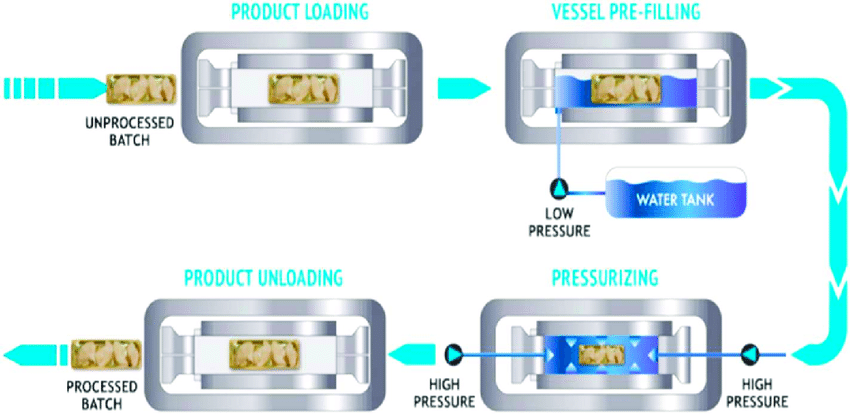

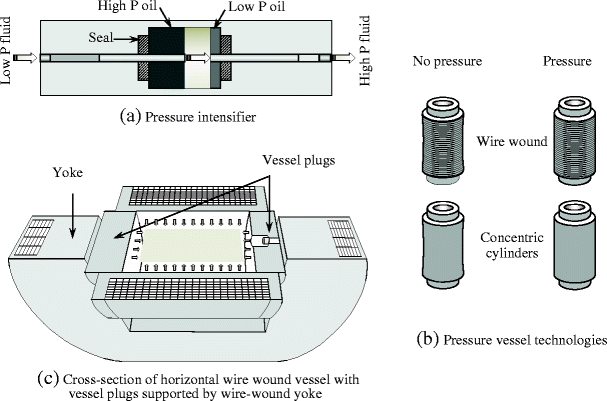

MICROBIAL High Pressure Processing of Foods - FSAI High pressure processing (HPP) is also called high hydrostatic pressure processing, ultra high pressure processing, pascalization or cold pasteurisation. It is a food processing technology which applies high pressure to solid or liquid foods to improve their safety and in some cases, organoleptic properties and quality. How does HPP work?

Universal Pure | Your HPP Service Provider The Benefits of High Pressure Processing (HPP) Brief is a great resource to learn how HPP can help food & beverage manufacturers, retailers, and food service companies to drive food safety, enable cleaner labels, enhance quality and extend the shelf-life of products. Learn More

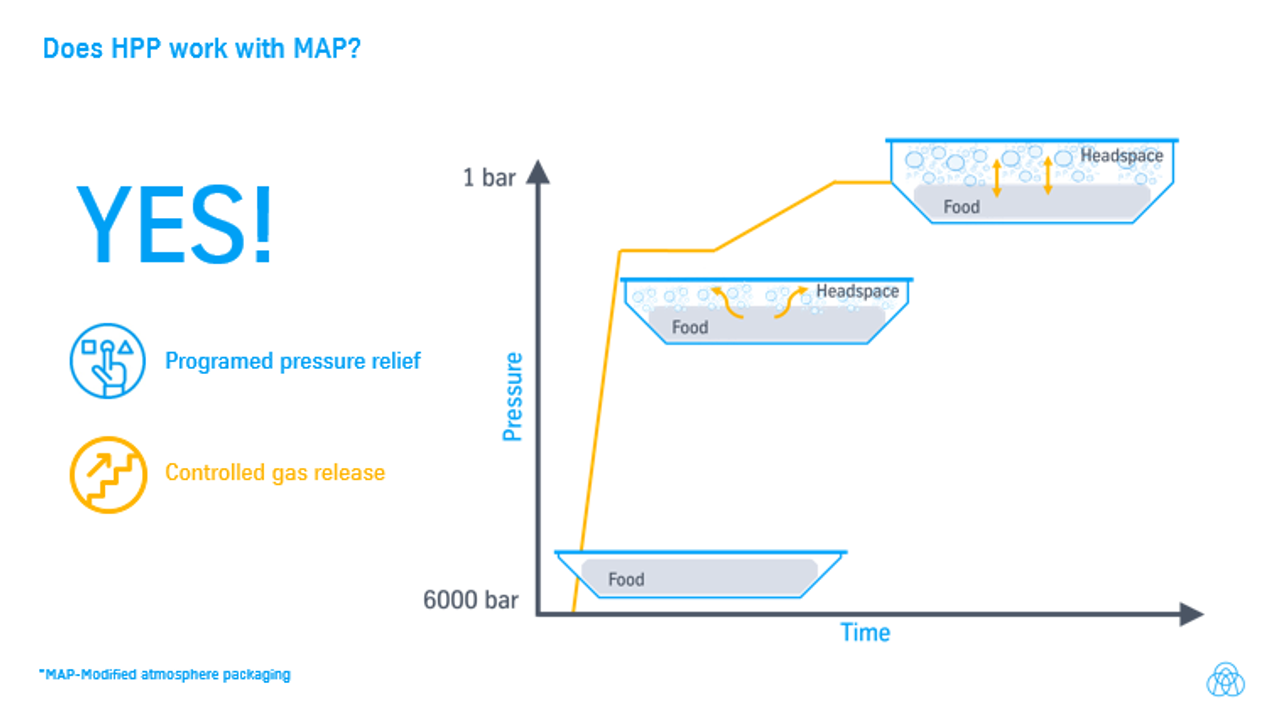

High-pressure processing: food safety without compromising quality HPP is a non-thermal food preservation technique that kills microorganisms that can cause diseases or spoil food. It uses intense pressure for a certain time and has minimal effects on taste, texture, appearance, or nutritional values. HPP can be used at different steps of the food chain, usually on pre-packed products.

High Pressure Processing (HPP) | MCC Label High Pressure Processing (HPP) is a cold pasteurization technique by which products, already sealed in their final packaging, are placed in a container and subjected to high pressure (87,000 psi). This inactivates the vegetative flora (bacteria, viruses, yeasts, molds and parasites) present in food, extending the product shelf life and ensuring food safety.

PDF High Pressure Processing - meatupdate.csiro.au high pressure can be more effective than continuous single application, so treatment times can be reduced (Hayakawa et al. 1994). High pressure processing is a very promising technology for ready-to-eat (RTE) meats because there are few barriers to approval by regulatory authorities, no special labelling requirements because no chemicals are used,

High pressure‐based hurdle interventions for raw and processed meat: a ... In the past decades, high-pressure processing (HPP) has been investigated as an alternative non-thermal preservation technology to match all these demands without compromising safety. HPP treatments could efficiently inactivate the vegetative microorganisms (related to foodborne diseases), but not spores.

High Pressure Jet Processing for Clean-Label Foods and Ingredients Toggle main menu visibility. Join; Sign in; Toggle communities menu visibility Communities

Verification Activities for High Pressure Processing, Irradiation and ... This directive provides instructions for inspection program personnel (IPP) to verify that official establishments meet regulatory requirements when they treat products with high pressure processing (HPP) or irradiation and send product to another official establishment for treatment with HPP or irradiation.

› meat-processingMeat Processing - an overview | ScienceDirect Topics E. Ortega-Rivas, in Encyclopedia of Food Microbiology (Second Edition), 2014 The Meat-Processing Industry. The meat-processing industry consists of establishments primarily engaged in the slaughtering of different animal species, such as cattle, hogs, sheep, lambs, or calves, for obtaining meat to be sold or to be used on the same premises for different purposes.

Benefits of HPP | hydrofreshhpp.com Unlike traditional heat processing, high pressure processing uses cold water and intense pressure so the nutritional and functional properties of the product remain intact. This allows for a natural, organic, preservative free product. HPP promotes the creation of healthier foods which are rich in vitamins and anti-oxidants as those properties ...

Pressure-sensitive Labels - Overview on Technology and Market The typical construction of a pressure-sensitive label consists of an adhesive-coated face stock on a carrier (= release liner). The release liner may be siliconized paper or film, low surface energy film, or other materials that do not permit adhesion of the adhesive coating until it is applied to the final destination (the primary substrate).

HPP - High Pressure Processing Solutions | FoodTech - JBT High-pressure processing has many benefits - both for the food products you're creating and for your facility operations. Maintains food's fresh, natural taste; Preserves vitamins and minerals; Hydrates and increases yields for seafood; Improves food safety; Provides a clean label solution; Extends shelf-life; Reduces waste and processing inefficiencies

The Basics of a Pressure Sensitive Label » Labeling News We are the experts in label converting and label applications. Our converting facilities can manufacture any type of label you might need, or we can help you create a custom label for a demanding application. Do you need to improve your labeling operations? ID Technology can help. Call us toll free at 888-438-3242.

High Pressure Processing (HPP) Advantages - Hiperbaric HPP allows R&D teams to develop innovative products for the consumer and open new market niches. Increases the Extraction Yield of Shellfish Meat. HPP, at low pressures (3,000 bar), is used for opening bivalve mollusks and removing meat from crustaceans, increasing efficiency and minimizing labor. Eco-friendly.

› article › 63090-meaningWhat Is the Meaning of Nutritional Value? | livestrong Oct 14, 2019 · According to the Mayo Clinic, added sugars are sugars and syrups that make their way into food during processing. They're commonly found in sodas, desserts, candy, energy drinks and more. The 2015-2020 Dietary Guidelines recommend dedicating no more than 10 percent of your daily calories to added sugars (which equates to 50 grams for a 2,000 ...

Post a Comment for "43 high pressure processing labels"